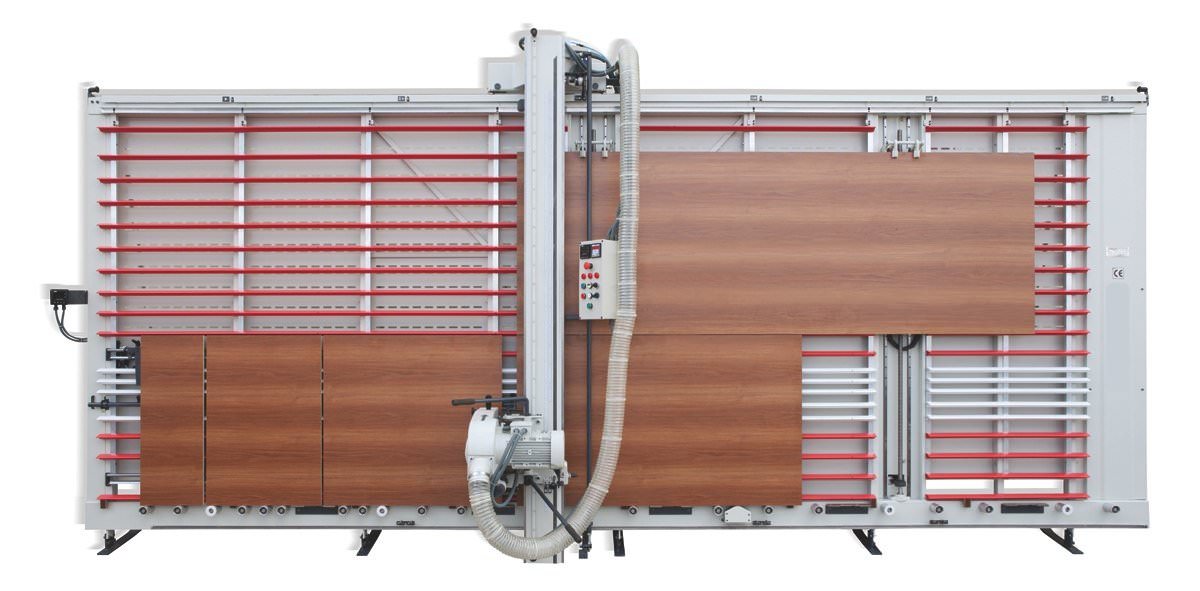

VERTICAL PANEL SAW MAKK Mod.DPM-KS WITH PLIERS SYSTEM FOR PANEL CLAMPING.

Cutting Panels mm.5100×2100 (2200). Automatic movable table.

Included: Engraving group and Digital Visualizer for vertical and horizontal cuts.

Machine for cutting panels either in vertical or in horizontal, for all cutting needs, with the best quality/price ratio on the market.

Panel Clamping System by Pliers.

The system of clamping pliers of panels used for the mod. DPM-KS, highlights once again its peculiarity in the vertical cut.

Thanks to this system, even one operator can cut in the desired dimensions great panels, too, without the least effort.

By the PLC control system you can make cuts with precision from 0,05 mm.

Through the pneumatic clamping system of the mod. DPM KS, panels can be trimmed in the lower part.

Therefore, operator’s work is extremely facilitated allowing to make a cutting operation without effort and with the maximum precision.

Engraver Group.

The engraver group of the machine allows to avoid the possible splinters that can be caused during the cutting operation of ennobled, veneered panels.

Panel Sliding System.

The double bearings wheels for panel sliding – of high quality and carefully worked – allow panels to slide freely on the machine.

Short Piece Device.

Thanks to this device, pieces of small dimensions can be easily cut without operator’s waste of time.

For cutting panels either in vertical or in horizontal, made of:

– Chipboard

– Ennobled chipboard

– Multilayer

– Massive wood

– MDF

– Plexiglass

– Polycarbonate

– Plastic materials

– Corian, etc…

- Completely welded frame, with panel support table with PVC-profiled listels, that can be moved automatically in order to avoid the contact with the circular blade in horizontal cuts.

- Manual deplacement of the upright with blade group to make vertical and horizontal cuts by means of manual lever. Manual governor of panel cutting depth

- Engraving group with circular conical blade, with belt transmission.

- Digital visualizer for the perfect adjustment of cuts in vertical and horizontal.

- Automatic movable table, with pneumatic operation.

- Panel Clamping System by Pliers.

- Tilting device for support of small pieces to be cut.

- Kit: angular cut device.

- Mechanical positioners for horizontal cuts.

- Nr. 2 wings for vertical cuts.

- Lower panel supports with metal wheels.

- Safety devices.

- Instruction manual and service keys.

- Circular blade.

Technical Data:

– Digital visualizer for the perfect adjustment of cuts in vertical and horizontal

– Panel Clamping System by Pliers.

– Movable table: Automatic

– Motor power: 4 HP

– Electric consumption: 3 kW

– Rotation speed: 3000 r.p.m.

– Rotation speed of the circular blade: 5800 r.p.m.

– Rotation speed of the blade of engraving group: 7800 r.p.m.

– Max. cutting height: 2100 mm

– Max. cutting length: 5100 mm

– Macutting thickness: 50 mm

– Dimension of the circular blade: mm. 250x30x3,2 Z=80 HM

– Dimension of the engraving blade: mm. 125x20x3 Z=24 HM Conical

– Overall dimensions (L x H x W): 6030 mm x 2980 mm x 1150 mm

– Packaging dimensions: frame (L x H x W): 6030 mm x 2500 mm x 450 mm

– Packaging dimensions: upright (L x H x W): 2500 mm x 1100 mm x 900 mm

– Total weight: 960 Kg.

On Request

– Increased horizontal cutting length up to mm. 8000

– Cutting height mm. 2200

– Motor HP 5,5

– Special voltage