Description

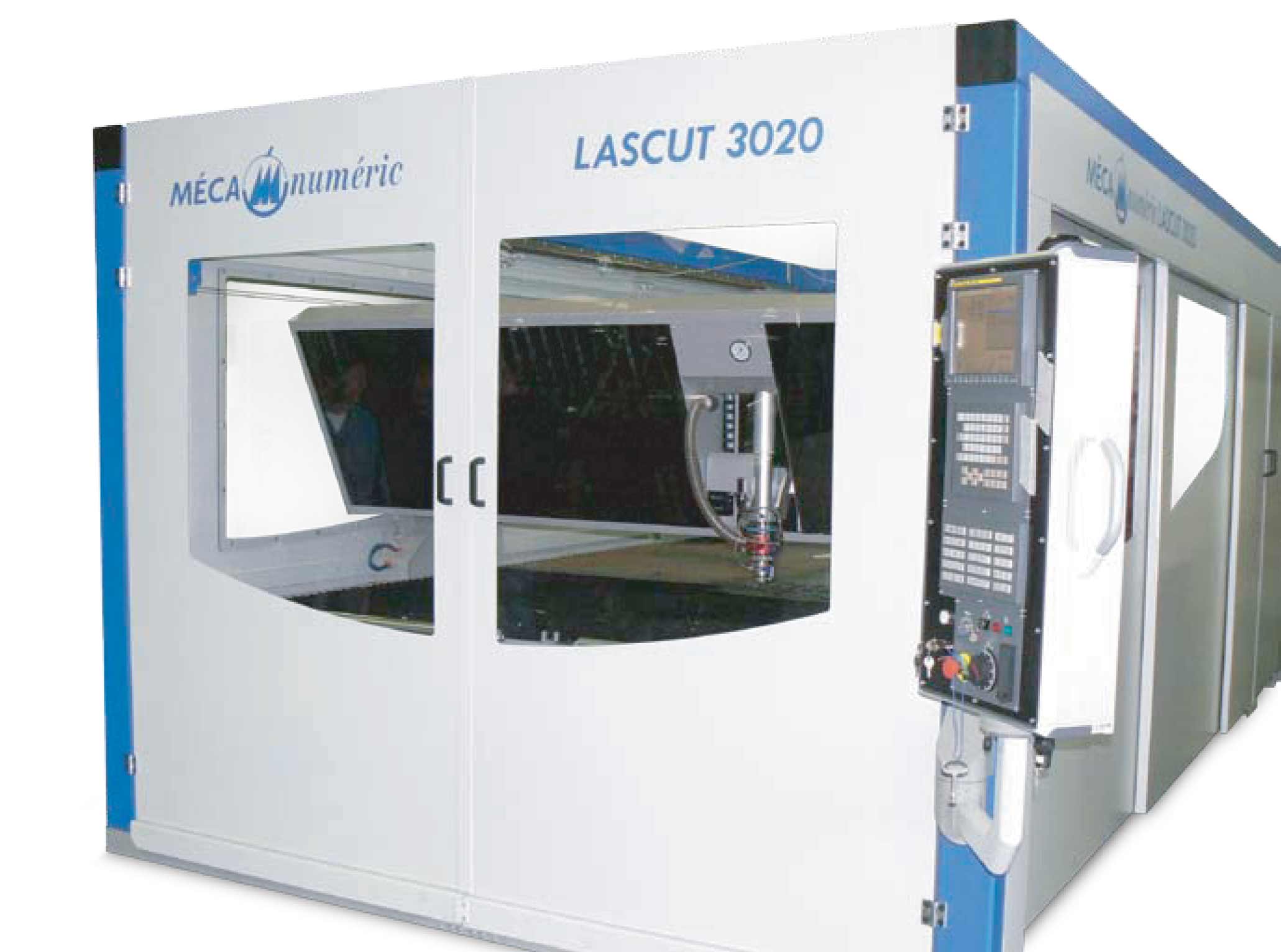

CUTTING AND ENGRAVING MACHINE “LASCUT” series

mod. ML-1510 – As per E.C. rules

The Cutting and Engraving Machine LASCUT series mod. ML-1510,

was projected in order to offer the best in production in the cutting stage.

The rigid and strong frame is built completely in welded steel, that assures

the maximum of precision and doesn’t cause any vibrazion in working stages.

Even this series was conceived assuring the maximum reliability and safety for operators

being the System completely protected by careening.

The sources installed on this series are the Top which market can offer.

DESCRIPTION

Structure: mobile gantry with welded steel structure

Table top: screened or anodized aluminium bars.

Guidance: prismatic guides

Transmission: endless screw (double screw for the X-axis).

Mirrors: gold-coated copper mirror.

Motorization: Brushless servomotors

Safety: as per E.C. rules, integrated shutter.

FEATURES

• CO2-laser cutting system

• Absolute power from 1.000 to 2.500 Watt

• Rigid frame in stabilized welded steel

• Fixed table and mobile portal.

• Feeding by endless screw on 3 axis

• High pressure focusing head.

• Motorization: Brushless servomotors.

TECHNICAL DATA

– X-axis stroke mm. 1505

– Y-axis stroke mm. 1020

– Z-axis stroke mm. 195

– max. width of materials mm. 1100

– passage under gantry mm. 200

– max. speed 300 mm./sec.

– resolution in mm. 0,004

– repeatibility ± 0,05

– length mm. 3400

– width mm. 1850

– height mm. 2160

– medium weight kg. 1800

FEEDING

Pneumatic feeding – Pressure: 6 bar / Delivery from 10 to 15 mc/h

Electric feeding: 3-phase 400 V 50 Hz + ground – from 25 to 60 A – Power according to configurations

NUMERICAL CONTROL

– Control MECANUMERIC CN7000 ISO with fixed disc 40 Gb.

– Numerical control SIEMENS SINUMERIK 840DI – 4 axis: X1-X2-Y-Z

– Numerical control FANUC 16OIL – 4 axis:X1-X2-Y-Z

– MHI on mobile keyboard with 15 inches touch screen

OPTIONS AND ACCESSORIES

• Smoke aspiration by suction group

• Aspiration and smoke treatment by suction group

• Spotting by red laser diode

• BRUSHLESS motors on 3 axis (max speed: 330 mm/sec.).

• Safety enclosure by PMMA panels + E.C. electric safety

• Mechanical control head of flatness defects

• High pressure capacitive head for metal cutting.

CO2 LASER SOURCES

LASER SLAB CO2 ROFIN SINAR-DC010 – Power 50 – 1000 W – Peak power: n.a. – Cooling: Liquid / Refrigerator group

LASER SLAB CO2 ROFIN SINAR-DC015 – Power 100 – 1500 W – Peak power: n.a. – Cooling: Liquid / Refrigerator group

LASER SLAB CO2 ROFIN SINAR-DC020 – Power 150 – 2000 W – Peak power: n.a. – Cooling: Liquid / Refrigerator group

LASER SLAB CO2 ROFIN SINAR-DC025 – Power 200 – 2500 W – Peak power: n.a. – Cooling: Liquid / Refrigerator group

QUICK FLOW LASER FANUC-C1000E – Power 50 – 1000 W – Peak power: n.a. – Cooling: Liquid / Refrigerator group

QUICK FLOW LASER FANUC-C2000E – Power 100 – 2000 W – Peak power: n.a. – Cooling: Liquid / Refrigerator group