Description

AUTOMATIC EDGEBANDER with glue pot for

light straight panels for the advertising and photographic industry –

Mod.K310 PHOTO FOAM

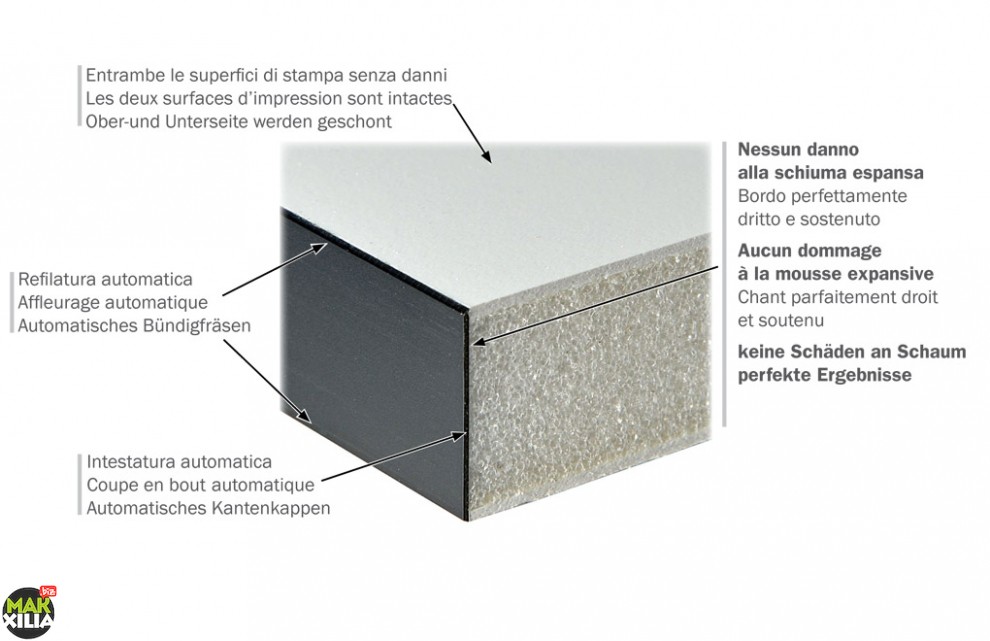

Edging, flush trimming and end trimming of light composite panels

Foad, Extruded, Honeycomb, Coupled with Light and Honeycomb Material

Simona®, Simopor®, Kapamount®, Kapafix®, Reboard® Etc.

The Automatic Edgebander – Mod. K310 PHOTO FOAM

has been conceived to edge without any problems any type of light panels.

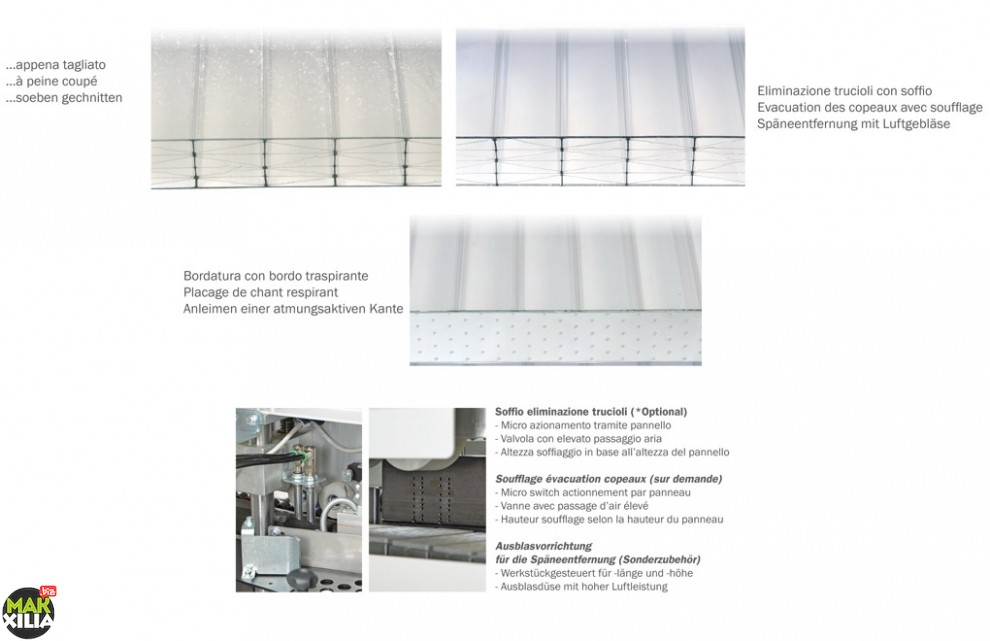

Particular attention has especially been taken on the units which are

in direct contact with the panel surface.

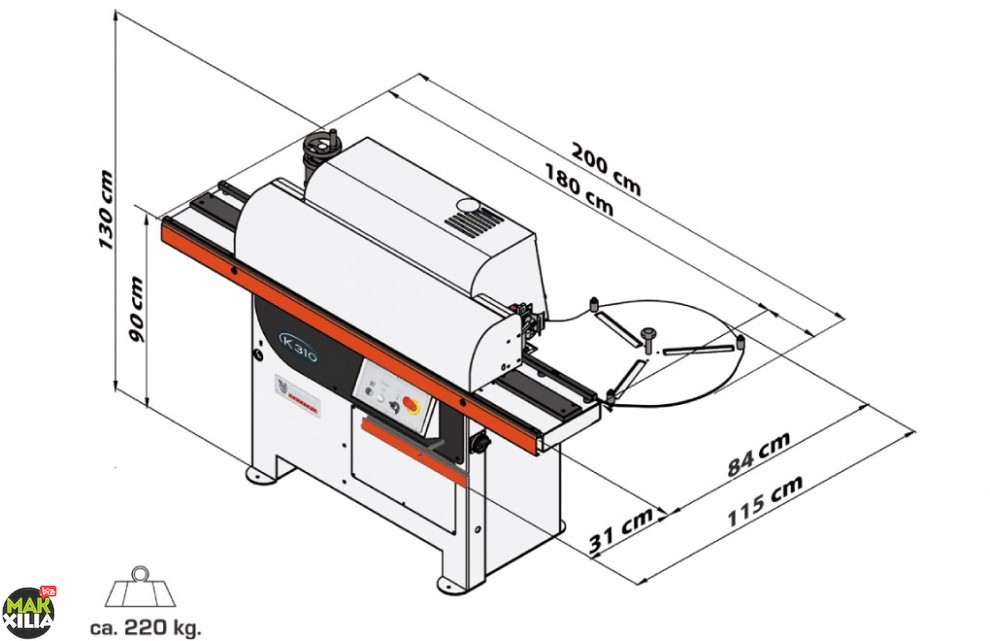

The K310 Photo Foam is a compact Edgebander with panel feed unit and glue pot to bond, end trim and flush trim edges upto to 1 mm thickness.

The feeding unit with three phase gear box and toothed belt allows to feed panels from 8 to 45 mm, whilst with the extensible support you can work larger panels.

The simple and compact construction allows a simple and intuitive use.

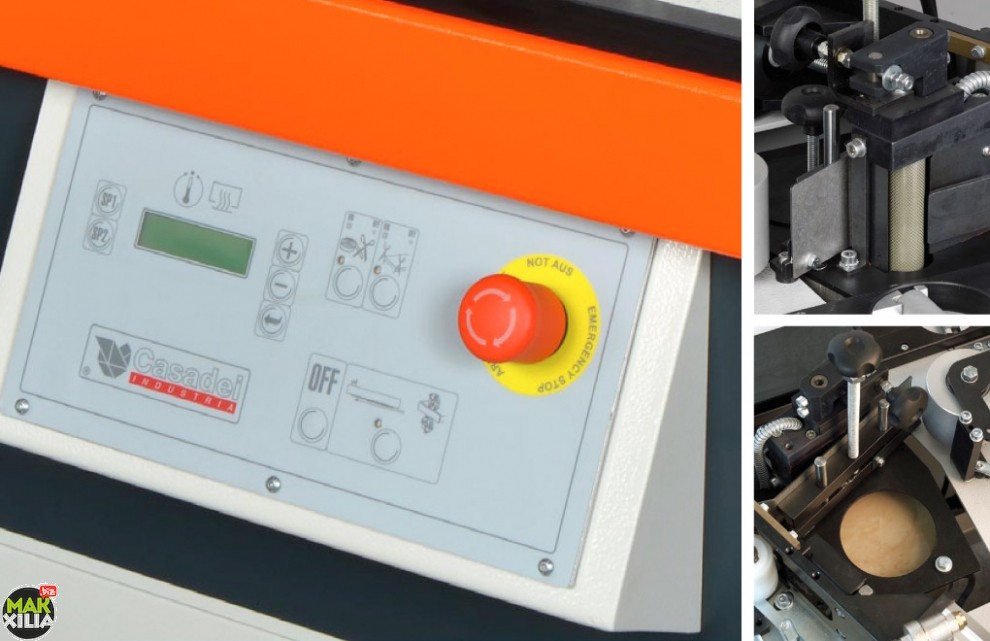

On the PlC, which is part of the standard equipment, you can see all the machine data,

like glue pot temperature, metres of edge used and how many hours has machine been working.

Moreover the maintenance messages are periodically indicated based on the working hours.

The teflon coated glue pot is controlled by the PLC and its glue spreader roller is

automatically activated when working temperature has been reached.

The Pneumatic end trimming unit with follow-up system and the automatic bevelled flush trim unit finish the edging in a precise and quick manner.

Advantages and Benefits:

Edging light panels:

- Better finishing on panel

- Sides of panels edged and protected

- Major protection during transport

- Hundreds of colours and finishings available

- No damage to the foam

- Edge completely straight and stiff

Machine:

- Ready to use in a few minutes

- Easy cleaning and maintenance

- Quick edge changing

- Quick adjustments according to edge used

- Automatic End Trimming

- Automatic Flush Trimming

Technical Data:

Panel thickness: min-max 8 – 45 mm

Edge thickness: min-max 0,4 – 1,0 mm

Heating elements power Nr. 5: ca. 1350 W

Flush trimming motor: 0,37 kW

Widia cutterblocks: 10.000 RPM – Ø 75 mm Z4 – bevel 15°

Total power installed: ca. 2 KW